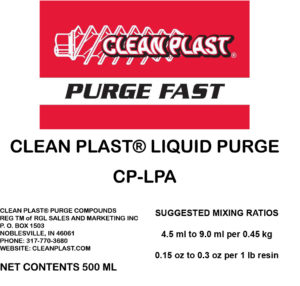

CLEAN PLAST® CP-LPA is a specially developed cleaning compound that is delivered in a premixed, concentrated and ready-to-use liquid form. It is specifically developed for the cleaning of screws, barrels, heads, and dies to remove burned material, color hang-ups, deposits and black specks during color and/or material changes specifically for all resins.

CLEAN PLAST® CP-LPA is a specially developed cleaning compound that is delivered in a premixed, concentrated and ready-to-use liquid form. It is specifically developed for the cleaning of screws, barrels, heads, and dies to remove burned material, color hang-ups, deposits and black specks during color and/or material changes specifically for all resins.

CLEAN PLAST® CP-LPA processing temperature range is from 250ºF to 750ºF (120ºC to 400ºC). It removes, at the temperature of the previously processed material any hang ups and deposits.

CLEAN PLAST® compound is not abrasive and works with a chemical reaction.

CLEAN PLAST® is manufactured with non-abrasive chemical components; colored and burned polymers, incrustations, black specks are removed and purged from the press.

There is “NO MECHANICAL ACTION” made on the Machine Parts or Tooling.

CLEAN PLAST® cleans at the processing temperature of the previous production material and no soak time is required. It is recommended for hot runners.

CLEAN PLAST® is not toxic and is odorless. It will not damage your equipment because it does not contain solvents: all components are qualified as GRAS (Generally Recognized as Safe) by FDA.

If used frequently, it will preserve all the equipment from steel oxidation that will make the cleaning process quicker and easier during the next cleaning operation. It cleans at the processing temperature of the previous production material and no soak time is required.

CLEAN PLAST® liquid purging compound is made to pass also through the smallest orifices of hot runner systems and valve gates.

Learn More at www.cleanplast.com