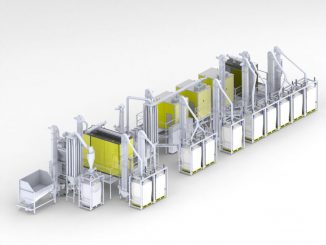

Charlotte, NC – April 2013 – The recycling specialists at Westeria Fördertechnik GmbH have optimized their product line of pusher plate bins.

Designed as proportioning or feed bins, these bins are used as a preliminary stage in the recycling or waste treatment process, feeding materials downstream at a continuous, controlled flow. Bin walls are built to ensure maximum useful inside width and volume. A variety of sizes and capacities are available.

The distinct feature of these newly designed bins lies in the design of the moving floor that consists of a series of bars that move back and forth. Consistent metering of the material to the downstream equipment is a main advantage of these bins.

Up to now, the push bars had to be aligned at site during a costly assembly to ensure the tightness of the system. According to a statement by the company, this is a thing of the past. Westeria bars for their movable floors are designed and manufactured in such a way that the axial center will always be retained. No matter in which sequence the bars are assembled, they will always fit and, consequently, can be positioned arbitrarily during assembly.

Additional practical features include a top-quality sealing system between the bars, the use of rotary drum feeders at the end of the push path as well as the stepless speed adaptation of the powerful motor with a low noise emission in both directions. These technical refinements go hand in hand with the apparent ruggedness of the low-wear steel structure, which can be adapted to any subgrade, ensuring access for trucks or wheeled loaders at any time, if the surface of the soil is smooth.

For more information about the distinct features and benefits of Westeria’s pusher plate bins contact eFACTOR3, LLC, their North American partner, at 1.877.801.3232, sales@efactor3.com, or visit them online at http://www.efactor3.com/.

Be the first to comment