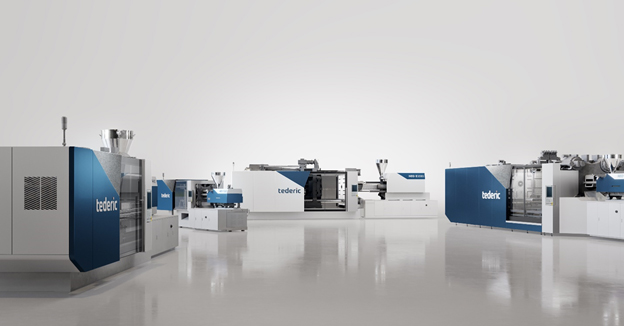

Tederic Machinery Co. launched its all-new premium injection molding machines at the recent Chinaplas 2021 in Shenzhen, China.

The NEO series has been jointly created by the Tederic team and a group of top designers from around the world, bringing together the accumulated Tederic engineering experience, with leading European design knowhow. The combination of leading industrial styling, advanced electro-mechanical design, and leading brand componentry, result in a machine with excellent performance and a premium user experience.

All machines feature an advanced Keba control, with the option of 12-inch touch, 15-inch multi-touch and 21-inch enhanced multi-touch configurations. The controllers offer support for OPC, UA and Modbus data protocols and feature free programming capabilities to accommodate a variety of special process requirements.

A new generation of servo-pumps power the system with ultra-high response speeds (max. pressure can be reached in 28ms) can save 30% to 80% energy consumption when compared to traditional hydraulic systems.

Machine guarding has been completely redesigned to align with the new Tederic brand and, aside from an aesthetically pleasing appearance, has also been engineered to be safe, practical and user friendly. All machines conform to the local safety standards in the various international markets where Tederic is sold.

Available in China immediately, with introduction to export markets phased in over the next six months. North American availability will be late 2021.

Six new product lines are introduced: NEO · T, NEO · E, NEO · Ec, NEO · H, NEO · Mv, NEO · Ms

NEO · T – a series of servo-toggle machines in the range 90t to 4000t. New features include larger tie bar spacing, enhanced mold height and a special clamp braking system to improve mold positioning accuracy.

NEO · E – all-electric machines in the range 55t to 460t. Features include larger tie bar spacing, NSK linear bearing for platen guidance, standard 15-inch touch screen, latest generation motors and drives with DC bus technology. Available with speed injection speeds up to 500mm/sec, pressure accuracy to <1bar, excellent low-speed control. Ideally suited for precision technical, medical and high volume thin-wall applications.

NEO · Ec – hybrid-electric machines in the range 55t to 460t. Injection, screw rotation and clamping unit are electro-mechanically driven, and there is an integrated power pack with servo-pump to power the ejectors, carriage and core pulls. The carriage has twin hydraulic pistons, and the moving platen features linear bearing guidance. A 15-inch touch screen is standard, and the machine uses the latest generation motors and drives with DC bus technology. Available with injection speeds up to 250mm/sec. Will appeal to custom molders who desire the accuracy of the electric solution, coupled with the flexibility of the integrated hydraulics.

NEO · H – two-platen servo-pump machines, initially available in the range 680t to 2700t (eventually through 4000t). Several new models with larger tie bar spacing, enhanced mold daylight, and a special clamp braking system to improve mold positioning accuracy. A 15-inch touch screen is standard, and the machine uses the latest generation motors and drives with DC bus technology. Available options include electric screw drive, tie bar extraction, and extended daylight with mold side-loading.

NEO · Mv – a range of multi-material machines that are equipped with the Spinsure-V™ vertical rotary platen integrated into the moving platen casting. These rotary platens are servo driven and offer a full range of utility connection options. Wide platen toggle machines in the range 170t to 810t and two-platen machines in the range 880t to 1920t can be configured with up to five independently controlled injection units. These units can be positioned parallel, angled, perpendicular and vertical to the main machine axis. Both hydraulic and electric injection units are available.

NEO · Ms – a special range of multi-material machines in the range 880t to 1920t that are equipped with the Spinsure-H™ horizontal rotary table that is positioned between the fixed and moving platens and is used to rotate the center section of a stack mold. The machine has two opposing injection units as standard, the secondary unit riding behind the moving platen.

Additional injection units can be added as required. The rotary table movement and positioning is independently controlled, allowing for a range of mold designs and complex applications.