Wood and paper are very common impurities in plastic recycling. Conventional filter systems using mesh screens are usually unable to manage even small amounts of such impurities. The patented Continuous Disk Filter (CDF) system by Austrian company, MAS – Maschinen-und Anlagenbau Schulz, however, easily filters and eliminates these contaminants.

Continuous Melt Filtration

The central component of the CDF system is a filtration disk rotating in the incoming flow of melt. This disk is made of tempered steel and has a pattern of fine perforations. The filter is highly efficient at holding back impurities from the melt that it lets through.

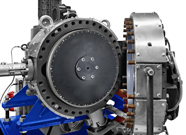

Available in four sizes, the basic modules have disk diameters of 300 or 510 mm and, depending on the type, either one or two filter disks are fitted. The newly introduced and largest system, the CDF 500-D (Image left), is designed with two filter units in parallel, which have a diameter of 510 mm. The available active filter area is a remarkable 3650 cm², allowing a melt throughput of between 1300 and 2000 kg/h. The “twin” configuration makes it possible to keep the dimensions extremely compact, ensuring that the filter is easy and flexible to handle, both during cleaning and maintenance and during transfers between a number of different extrusion lines when required.

Available in four sizes, the basic modules have disk diameters of 300 or 510 mm and, depending on the type, either one or two filter disks are fitted. The newly introduced and largest system, the CDF 500-D (Image left), is designed with two filter units in parallel, which have a diameter of 510 mm. The available active filter area is a remarkable 3650 cm², allowing a melt throughput of between 1300 and 2000 kg/h. The “twin” configuration makes it possible to keep the dimensions extremely compact, ensuring that the filter is easy and flexible to handle, both during cleaning and maintenance and during transfers between a number of different extrusion lines when required.

Self-cleaning System

To ensure the disk filter does not clog up in continuous operation, a scraper removes the contamination from the surface of the rotating screen disc. The impurities are discharged continuously from the CDF, while the filtrated melt is forwarded to the pelletizing system.

Easy Maintenance:

Easy Maintenance:

Filter Disc Replacement Despite the considerably larger dimensions and masses of its components, the CDF 500-D filtration unit is just as easy to maintain as the smaller models of the same type, thanks to its split housing, hinged connections and integrated service crane (Image left). Consequently, the filter screen can be replaced in approximately 45 minutes using conventional tools, and can be reused numerous times.

For more information about Continuous Melt Filtration and the CDF 500-D from MAS contact eFACTOR3, LLC at 1.877.801.3232, sales@efactor3.com, or online at http://www.onesteprecycling.com/.

Visit MAS at K 2013 in Düsseldorf, Germany from October 16 – 23, 2013, Hall 09/B56.

About eFACTOR3, LLC

Headquartered in Charlotte, North Carolina, eFACTOR3, LLC brings together a keen understanding of environmental, engineering and equipment issues.

The company offers a variety of plastic cleaning, extrusion and compounding equipment along with pre-shredding, shredding and granulating machinery, conveying and separation lines, and integration and installation.

Whatever you intend to recycle or turn into an alternative fuel eFACTOR3 can provide a custom solution to meet your needs.

Contact us at 1.877.801.3232, sales@efactor3.com, http://www.efactor3.com/.

Be the first to comment